Direct fastening: Our screw brands KUNST & TAP

- GEVAG KUNST

- GEVAG TAP

- GEVAG PLAST

- GEVAG KSG

Our GEVAG Proprietary Brands

The screws of our established brands GEVAG KUNST and GEVAG TAP enable efficient and reliable direct fastening. The proven GEVAG KUNST screw is developed and optimized for direct fastening in thermoplastics. As a high-performance thread-forming screw, GEVAG TAP offers quick and secure connection assembly for steel as well as light and non-ferrous metals. The advantage: Thanks to the thread-forming screw, work steps and costs associated with otherwise necessary thread cutting, thread cleaning, and the tools required for these processes are eliminated.

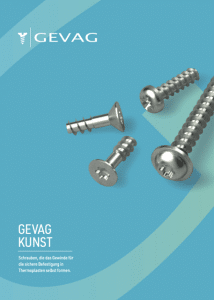

GEVAG KUNST

Screws that cut their own threads and reliably grip thermoplastics.

Screws of the GEVAG KUNST brand are developed for self-tapping direct screwing into thermoplastics. They use the ductility of the material, form the thread without cutting, and strengthen it for a particularly secure connection.

A large thread pitch, small core diameter, and a flank angle of 30° enable low screwing torques, high pull-out strength, and prevent material damage such as cracking or bulging.

Advantages

What makes GEVAG KUNST special

- Small radial forces – low radial expansion

- Low insertion torque

- Enormous load capacity due to high thread load-bearing capability

- No material damage

- Individually configurable in many different head shapes and thread diameters (1.8 – 6 mm)

Used in these industries

Typical applications at a glance

- Household appliances

- Medical technology

- Energy sector

- Automotive

GEVAG KUNST data sheet

The GEVAG KUNST data sheet provides a clear summary of all relevant technical details, dimensions, and application notes. The download offers a reliable basis for construction and planning.

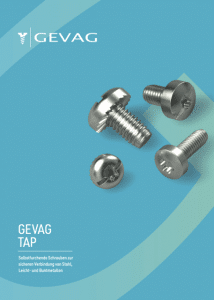

GEVAG TAP

Self-tapping screws for secure connections in steel, light and non-ferrous metals

The thread-forming screws according to DIN 7500 of the GEVAG TAP brand form metric threads in steel as well as light and non-ferrous metals. Thanks to their trilobular thread form, they can be screwed into drilled or punched holes without pre-cutting, creating a metric ISO mating thread without cutting and with low screwing torque.

The result is a play-free thread with high frictional engagement, which can also accommodate standard screws. GEVAG TAP is available in many head shapes, tool holders and thread diameters from M2 to M6 and can be individually configured.

Advantages

What makes GEVAG TAP special

- No separate thread cutting necessary

- Cost savings of up to 30% compared to screws requiring a tapped hole

- The formed thread is metric, allowing a standard screw with an ISO thread to be used

- No chips during the screwing process

- Screwing with low effort due to low forming torque

Used in these industries

Typical applications at a glance

- Automotive

- Mechanical and plant engineering

- Household appliances

GEVAG TAP data sheet

The GEVAG TAP data sheet provides a clear summary of all relevant technical details, dimensions, and application notes. The download offers a reliable basis for construction and planning.

GEVAG PLAST

Screws for the secure connection of plastics and light metals

Our

The specific properties are: large thread pitches, small core diameters, trilobular thread cross-sections.

Advantages

What makes GEVAG PLAST special

- Good resistance against vibrational loosening

- High pull-out and extraction strength

- Low insertion torque

- Reduced risk of cracking

- Small core diameters

Used in these industries

Typical applications at a glance

- Household appliances

- Medical technology

- Energy sector

- Automotive

GEVAG PLAST data sheet

The GEVAG PLAST data sheet provides a clear summary of all relevant technical details, dimensions, and application notes. The download offers a reliable basis for construction and planning.

GEVAG KSG

Screws with plastic saw thread

GEVAG KSG screws with plastic saw thread are designed for direct screwing into light metals and high-strength plastics and have been proven for many years. The asymmetrical, saw-tooth-like thread absorbs the forces generated during screwing in a targeted manner.

Assembly takes place in injected or drilled core holes with low screwing torque. A small thread pitch and a flank angle of 27° ensure high pull-out strength in high-strength plastics and reliably prevent cracking.

Advantages

What makes GEVAG KSG special

- Low insertion torque

- Very good assembly properties for direct fastenings

- Enormous load capacity due to high thread load-bearing capability (thread parameters: P, d1...)

- Individually configurable in many different head shapes and thread diameters

- Optionally available with scraping slot (DIN 4753)

Used in these industries

Typical applications at a glance

- Household appliances

- Mechanical engineering

- Medical technology

- Energy & Electronics sector

GEVAG KSG data sheet

The GEVAG KSG data sheet provides a clear summary of all relevant technical details, dimensions, and application notes. The download offers a reliable basis for construction and planning.

Request a non-binding consultation

Contact us! Our experts look forward to assisting you.

Why GEVAG?

Since 1879, GEVAG has been dedicated to the development and manufacturing of fastening elements. Our products range from screws, bolts, nuts, set screws, and washers to securing elements, stamped and bent parts, and turned and milled parts. We supply custom-made products and standard parts according to DIN and ISO. We meet requirements in thermoplastics, steel, as well as light and non-ferrous metals with our KUNST and TAP brands. GEVAG is your powerful single-source partner.